Engineered equipment for reliable water & wastewater operations.

E&I Corporation designs, builds, and supports high-performance clarifiers, collectors, and process components that help municipal and industrial plants run cleaner, longer, and more efficiently.

1975

Since

5 Decades of Experience

Municipal and industrial

water and wastewater

applications.

>

Commitment to the

highest standards of

Service and Quality

>

Time-tested treatment

methods with practical,

cost-effective solutions

>

Maximum uptime and operational efficiency

Welcome to E&I Corporation, where proven engineering meets modern water treatment. Since 1975, we’ve designed and built high-performance process equipment for the critical water and wastewater applications across North America.

We deliver superior, practical solutions that balance innovation with unwavering reliability. From municipal plants to complex industrial systems, our broad line of equipment is ready to meet your challenge. Discover how our expert recommendations and decades of experience can bring economic and operational excellence to your next project.

Superior Products & Reliability

-

Our Solution

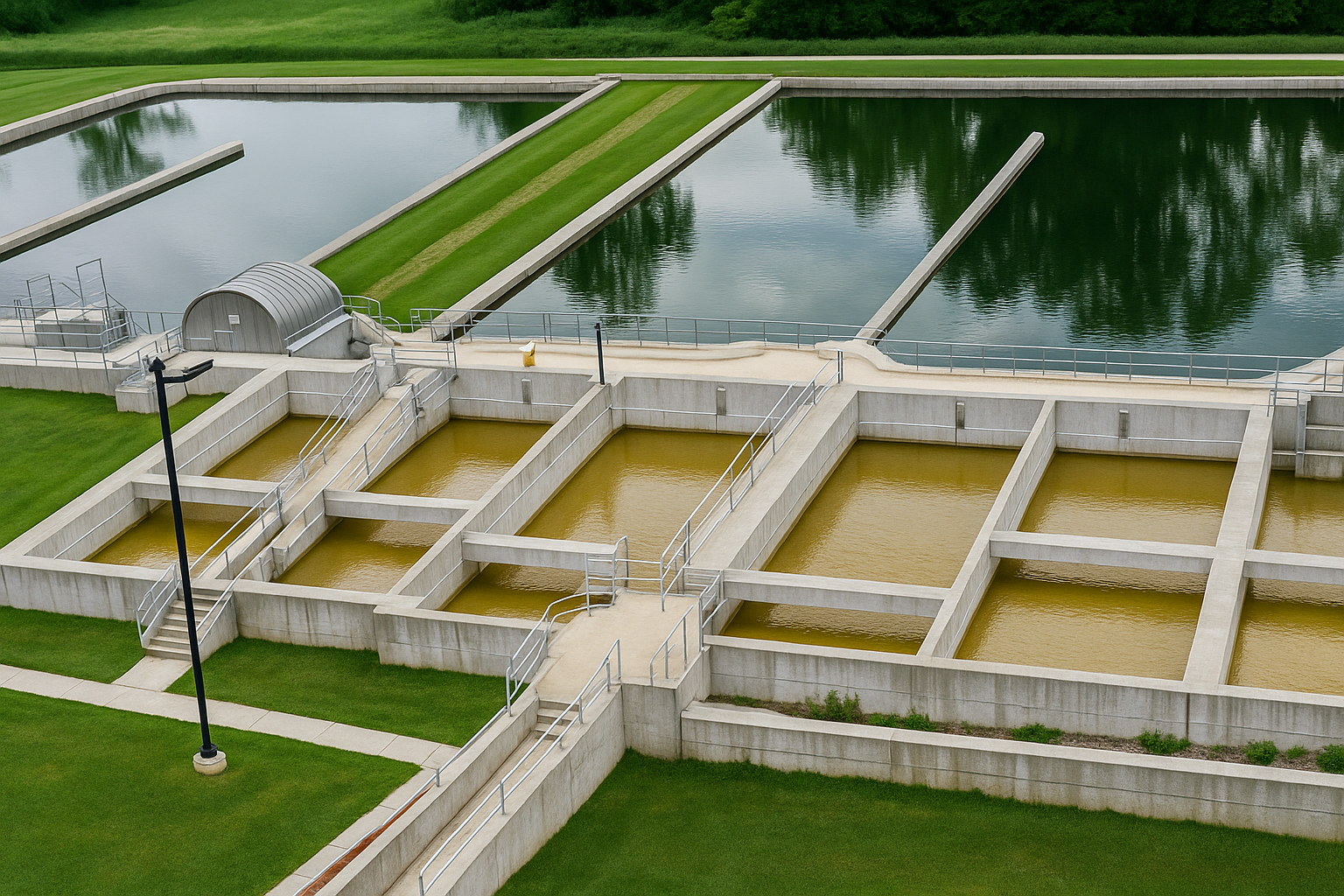

Nine Horizontal Flocculators & nine Rectangular Collectors

Lightweight, corrosion-resistant non-metallic materials

Reduced maintenance and long service life

Overview

Serving more than 47,000 residents, Newark’s water system draws from the Licking River and treats it through a network of 188 miles of water lines. To optimize reliability and reduce maintenance, the city partnered with E & I Corporation to install nine Horizontal Flocculators and nine Rectangular Collectors.

Each unit incorporates advanced, lightweight, corrosion-resistant materials engineered for longevity. The design minimizes maintenance downtime and supports efficient floc formation and solids collection.With over 25 years of proven operation, Newark’s installation demonstrates how innovation in material selection — from reinforced fiberglass to precision-molded plastics — extends equipment life and enhances water quality across municipal systems.

-

Key Highlights

Installed in 1978 and still operating with minimal maintenance

No underwater parts requiring replacement

Fully automatic, mechanized cleaning

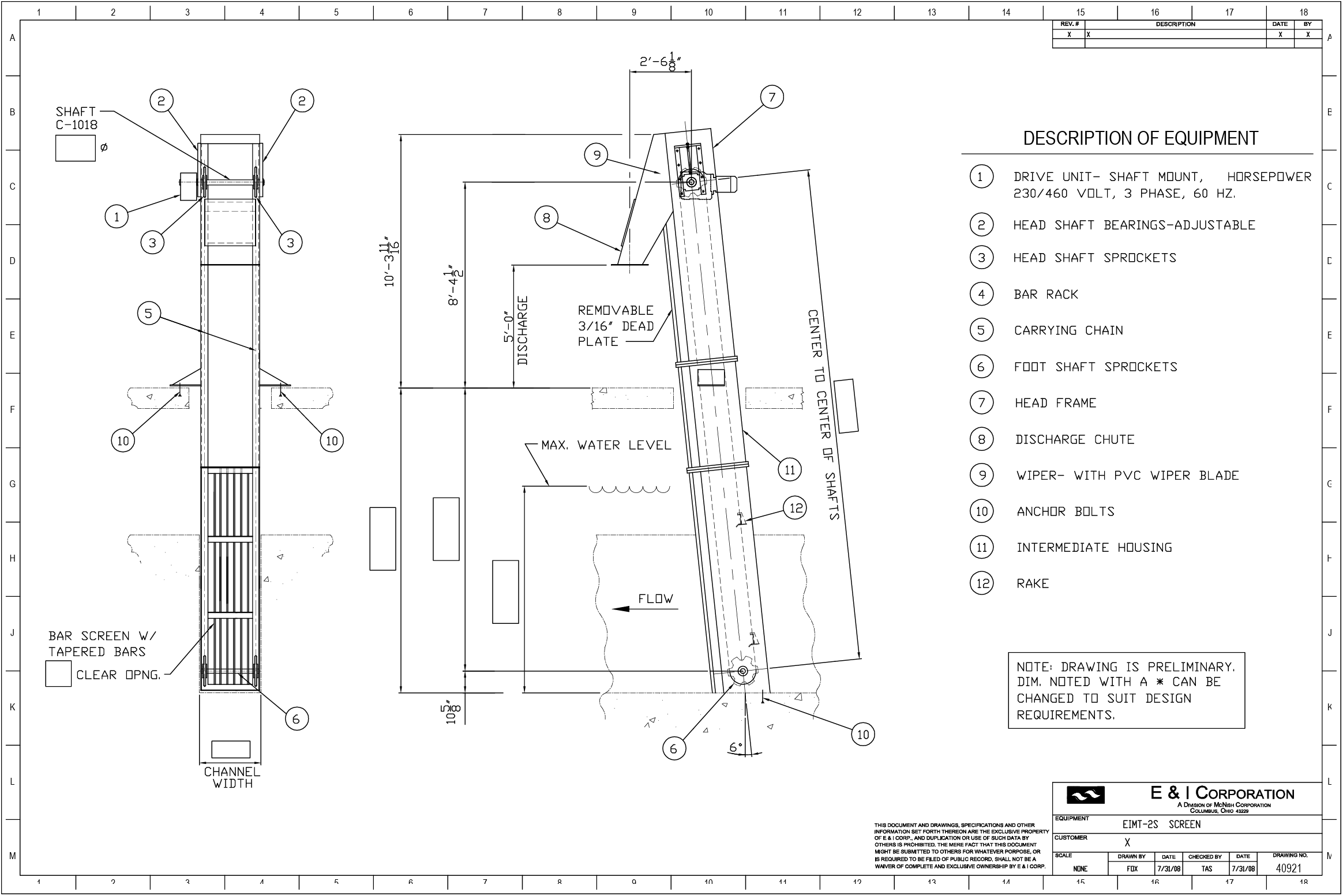

Protects downstream pumps & process equipment

Overview

Since 1978, the Glenbard Wastewater Authority has relied on E & I Corporation’s Catenary Bar Screens to safeguard its primary treatment system. Operating continuously through countless flow events, these heavy-duty, front-cleaned screens provide dependable performance with minimal attention.According to Senior Operator Erick Lanphier, “These screens have had absolutely no problems — they’re dependable workhorses.” By intercepting debris before it reaches raw pumps, the screens extend the mechanical life of downstream equipment and maintain biological process stability.

Working in tandem with nearby Lombard’s E & I installations, the Glenbard facility handles peak combined sewer overflows of 50 MGD. Over 25 years of uninterrupted service prove why the Catenary Bar Screen — often copied, never duplicated — remains the benchmark for rugged reliability in municipal screening.

-

Key Highlights

Installed in 1978; decades of operation with no major repairs

Screens an average of 7.5 million gallons per day

Serves 13,000 connections across a 36,000-person community

Durable carbon-steel frame & fiberglass covers

Overview

Westerville’s E & I Traveling Water Screen has achieved what most equipment only promises — 33 years of uninterrupted, maintenance-free operation. Installed in 1978, the system continues to screen an average 7.5 MGD from the Alum Creek River without any major component replacement.Built from rugged carbon steel and fiberglass-reinforced components, the screen’s dual-chain, basket-mesh system efficiently removes debris while minimizing mechanical wear. Its longevity is a testament to E & I Corporation’s precision engineering and fabrication standards, trusted by leading consultants such as Burgess & Niple, Black & Veatch, and the U.S. Army Corps of Engineers.

Decades later, Westerville’s screen continues to exemplify durability, reliability, and the high performance synonymous with E & I Corporation water-screening systems.

Case Studies

Time Tested Quality

E & I Corporation engineers and manufactures time-tested water and wastewater treatment equipment that delivers decades of dependable, maintenance-free performance in the harshest environments.

Extend the Life of Your Equipment: Genuine Parts & Expert Repairs

Even the most robust equipment eventually requires maintenance. Our dedicated repair and rehabilitation team at E&I Corp is here to assist you in identifying the exact parts you need to keep your water and wastewater treatment systems running efficiently.